Automatic laser welding machining sample pictures

Laser welding for medical accessories |

|

Kitchen and bathroom bath equipped with laser welding |

Sensor laser welding |

|

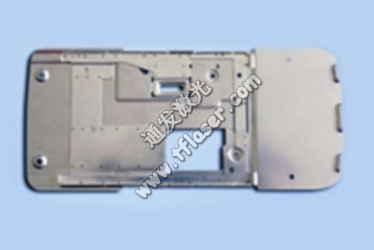

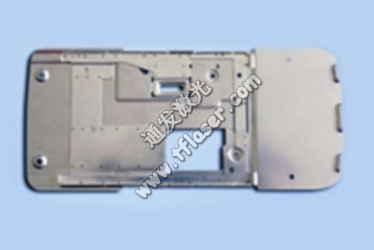

Laser welding of mobile phone case |

Instrument instrument laser welding |

|

Glasses glasses holder laser welding |

Standard workbench

|

|

Laser welding machine electric workbench

The table can be selected stepping motor table or servo motor table.

Optional X * Y bench length: 250 * 150 (standard), 300 * 200,400 * 200. |

Attachment and consumables

|

|

Laser pulse xenon lamp

Pulse xenon lamp chooses high quality ultraviolet filter quartz tube as the tube material, with high mass density electrode as the electrode of xenon lamp, has strong load capacity, high pump efficiency, good laser beam quality, long life and other characteristics. |

|

|

Laser welding machine protects the lens

Mainly protect the high value of the focus lens. Avoid welding smoke splashing and dust pollution to the lens lens. |

|

|

applied range

The main function of the filter element is to remove solid, colloid and other debris in the water, clean the cooling water, and protect the laser. |

Applied range

Application range of common laser welding machine TFL-180V / 300V can weld both mold and welding products, wider application range; [] electric workbench, one-hand operation mold welding is more convenient. All Chinese teaching programming, easy to learn to understand, product automatic welding is efficient and fast. Electronics industry: battery shell sealing, welding of plug-ins, laser welding of mobile phone, digital camera, MP4 and other electronic products. Hardware industry: sanitary ware, tools, accessories, tableware, lighting, etc Automobile industry: engine cylinder cushion, hydraulic tappet seal welding, spark plug, filter welding. Medical industry: the welding of stainless steel seals and structural parts of medical devices.

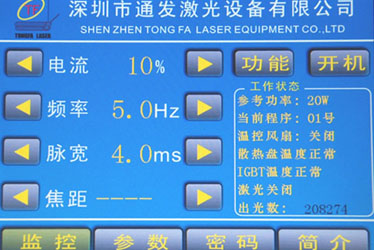

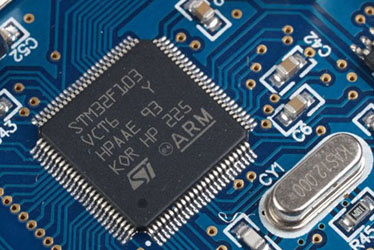

Professional laser power supply control system

The laser welding machine TFL-180V / 300V can weld mold and welding products, wider application range; [] electric workbench, one hand operation mold welding is more convenient. All Chinese teaching programming, easy to learn to understand, automatic welding efficient and fast.

Electronics industry: battery shell sealing, welding of connecting plug-ins, laser welding of mobile phone, digital camera, MP4 metal shell, structural parts and other electronic products.

Hardware industry: sanitary ware, tools, accessories, tableware, lighting, etc

Automobile industry: engine cylinder cushion, hydraulic tappet seal welding, spark plug, filter welding.

Medical industry: the welding of stainless steel seals and structural parts of medical devices.

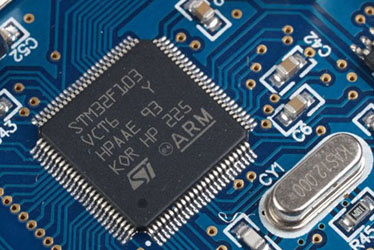

Professional laser power supply control system

1. The function of the whole machine is based on the adjustment of the output current, to control the correction laser output, so as to efficiently and safely use the laser for welding;

2. The main controller adopts the new ARMv 7 series processor, which has a high processing speed to meet the real-time control of the equipment. Fast and high-precision control and protection of the laser machine. Maximum possible to provide customers with fast and safe use experience.

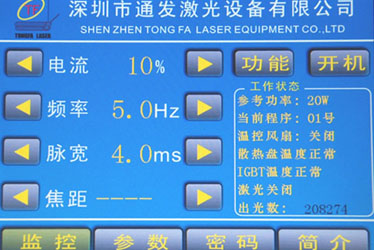

Main interface of common transmission laser power supply |

|

Main controller of the common transmission laser power supply |

3. The use of touch screen to do human-computer interaction, intuitive interface, clear display, various parameters are easy to understand and adjust, simple and easy to use;

4. The software has a strict control logic, fine digital filtering, fast control algorithm, so that the laser output is stable, fast;

5. With a variety of protection measures, to ensure the safety of the equipment and personnel.

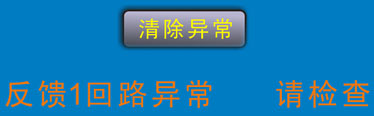

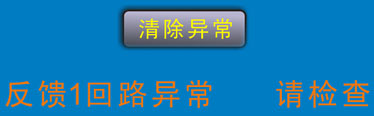

Open laser power alarm interface

Professional laser welding motion control system

The common laser welding control system is an embedded 3 D laser welding control system with the microprocessor as the core.

1. Support single point and continuous welding; [] has any straight line, arc, ellipse insertion function;

2. With delay, output, specified output port, waiting for input and other instructions, convenient to achieve the realization of the customer's own special process;

3. You can input coordinates by manual input or teaching, and support copying multiple copies by matrix.

4. The number of single file lines is 100,000 lines, and the number of files is 48;

5. At the same time, it can control the motor of four axis. Any axis with the function of linear insertion of hardware has the advantages of fast insertion speed and smooth connection.

Open laser welding control system interface |

Open laser welding control system interface |

Open laser welding control system interface |

Core laser

Laser-ceramic reflective chamber

1. The laser rod adopts the large brand YAG laser rod, with stable quality.

2. Laser output using small spot design, make the light spot smaller, suitable for welding small piece and precision workpiece.

3. The laser cavity uses the diffuse reflection ceramic reflection cavity, the laser conversion efficiency is high.

4. The equipment can choose microscope monitoring or camera system monitoring, that can be mold welding, can also be automatic welding.

Product Parameter

|

Model |

TFL-180V |

TFL-300V |

|

Laser wave length |

1064nm |

1064nm |

|

Concentration cavity reflector |

Imported ceramic concentrating chamber |

Imported ceramic concentrating chamber |

|

Laser power |

180W |

300W |

|

Pulse length |

0-15ms |

0-20ms |

|

Laser frequency |

0-50Hz |

0-200Hz |

|

The scope of light spot regulation |

0.3-2mm |

0.3-3mm |

|

Aiming at positioning |

Cross cursor and red light (optional camera system) |

Cross cursor and red light (optional camera system) |

|

Positioning accuracy |

±0.02mm |

±0.02mm |

|

Cooling power of the water chiller |

1.5P |

3P |

|

Table stroke |

200×300mm |

200×300mm |

|

Power rating |

6.5KW |

14.5KW |

|

Electricity demand |

Three-phase 380v ± 5% / 50Hz / 20A |

Three-phase 380v ± 5% / 50Hz / 40A |

|

External size |

Host machine:680×1400×1400mm

Water Chiller:540×650×780mm |

Host machine:680×1400×1400mm

Water 600×900×1300mm |