Picture of the lens laser welding machining samples

Laser welding of the electronic connectors |

|

Laser welding of mobile phone structural parts |

Laser welding of stamping small hardware pieces |

|

Button battery ear electrode laser welding |

Laser spot welding on the back side of the stud |

|

Iron shell laser welding |

Applied range

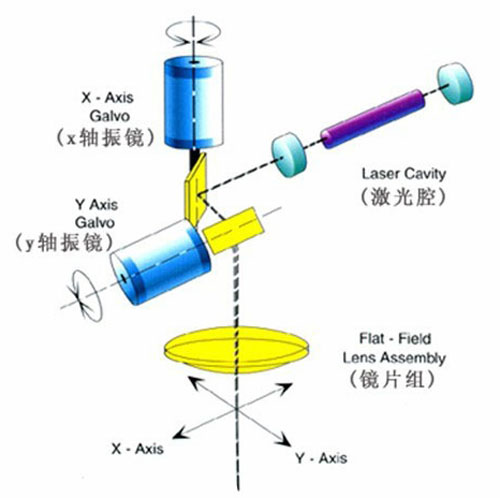

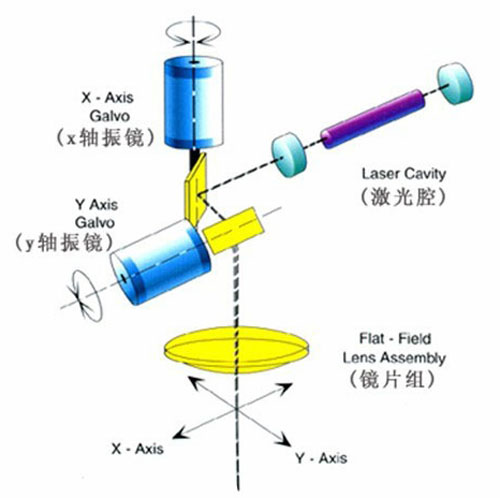

Mirror scanning laser spot welding machine is the introduction of foreign technology, the key components with high quality imported parts production, welding machine, using the scanning lens process of dynamic welding, and scanning the movement instead of the workpiece moving or welding lens group move, make lens lens in the scanning lens will laser beam quickly switch between solder joints, the greater the distance between the solder joint, the more the number of solder joints on the workpiece, the more obvious advantage. In the single point welding, because the empty-range positioning time is greatly reduced, the production efficiency is 4- -10 times higher than the laser spot welding of the ordinary XY workbench.

1. Using high-speed scanning lens for laser positioning, the speed can reach 7000 mm/s, which greatly reduces the empty walking time between welding positions, thus greatly improving the production efficiency;

2. Digital vibrator interface, strong anti-interference ability, better stability;

3. All Chinese special control components, powerful, simple operation, compatible with a variety of format map files;

4. High-power heat dissipation system, to meet the continuous work of mass production.

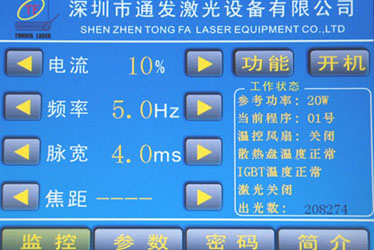

Professional laser power supply control system

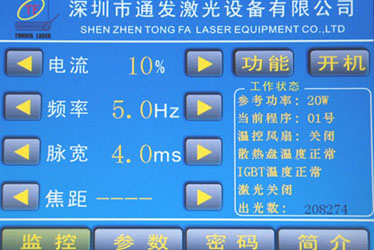

1. The function of the whole machine is based on the adjustment of the output current, to control the correction laser output, so as to safely and effectively use the laser for welding;

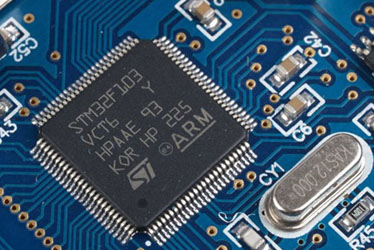

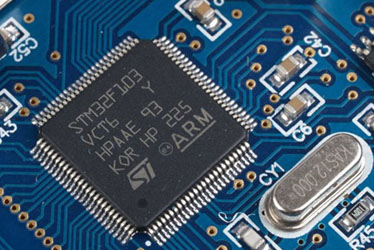

2. The main controller adopts the new ARMv 7 series processor, which has a high processing speed to meet the real-time control of the equipment. Fast and high-precision control and protection of the laser machine. Maximum possible to provide customers with fast and safe use experience.

Main interface of common transmission laser power supply |

|

Main controller of the common transmission laser power supply |

3. The use of touch screen to do human-computer interaction, intuitive interface, clear display, various parameters are easy to understand and adjust, simple and easy to use;

4. The software has a strict control logic, fine digital filtering, fast control algorithm, so that the laser output is stable, fast.

Open laser power alarm interface

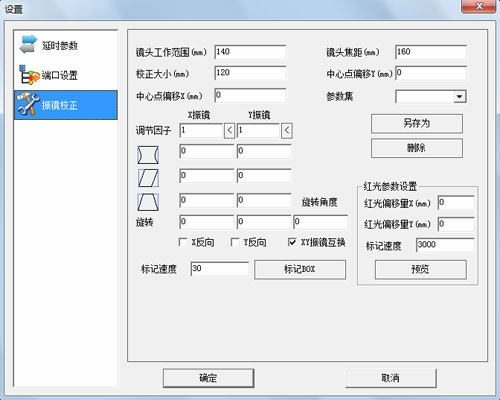

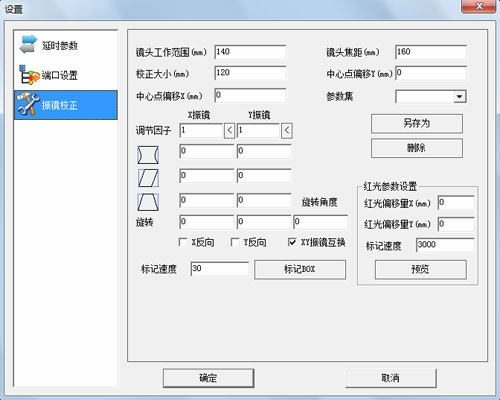

Professional scope laser welding control system

1. The common laser vibration scope welding control system is a laser welding control system with PC as the core.

2. Flexible configuration, convenient and direct adjustment and debugging. Support trapezoidal correction, barrel correction, and parallelogram correction.

3. Convenient editing functions, such as living in the center, moving, rotation, tilt, mirroring, array, replication, analog replication, etc.

4. Support extended motion axis, can bring two motors. Support angle rotation tag and bench straight motion control.

Core laser

Adopt imported ceramics, diffuse reflection, corrosion resistance |

|

Double steps design, change the lamp to wash the cavity more convenient |

|

Gilded lamp clamlet, excellent conductivity without heat |

Attachment and consumables

|

|

Laser pulse xenon lamp

Pulse xenon lamp chooses high quality ultraviolet filter quartz tube as the tube material, with high mass density electrode as the electrode of xenon lamp, has strong load capacity, high pump efficiency, good laser beam quality, long life and other characteristics.

|

|

|

Open laser chiller filter element

The main function of the filter element is to remove solid, colloid and other debris in the water, clean the cooling water, and protect the laser. |

Product Parameter

|

Model |

TFL-180SW |

TFL-300SW |

|

Laser wave length |

1064nm |

1064nm |

|

Concentration cavity reflector |

Imported ceramic concentrating chamber |

Imported ceramic concentrating chamber |

|

Laser power |

180W |

300W |

|

Pulse length |

0-15ms |

0-15ms |

|

Laser frequency |

0-50Hz |

0-200Hz |

|

The scope of light spot regulation |

0.3-2mm |

0.3-2mm |

|

Aiming at positioning |

Glow |

Glow |

|

Positioning accuracy |

±0.01mm |

±0.01mm |

|

Cooling power of the water chiller |

1.5p |

3p |

|

Power rating |

6.5KW |

14.5KW |

|

Electricity demand |

Single phase 220v±5%/50Hz/30A

Three-phase 80v±5%/50Hz/20A |

Three-phase 380v±5%/50Hz/40A |

|

External size |

Host machine:720×1400×1300mm

Cooling-water machine:540×650×780mm |

Host machine:720×1400×1300mm

Cooling-water machine:600×900×1300mm |