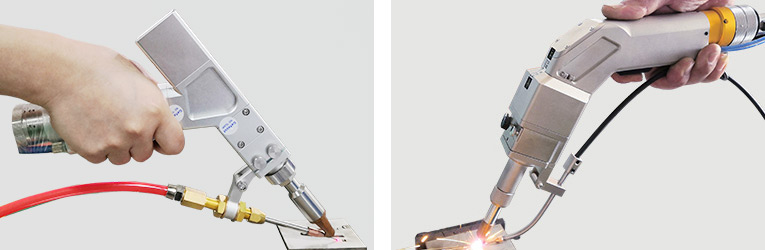

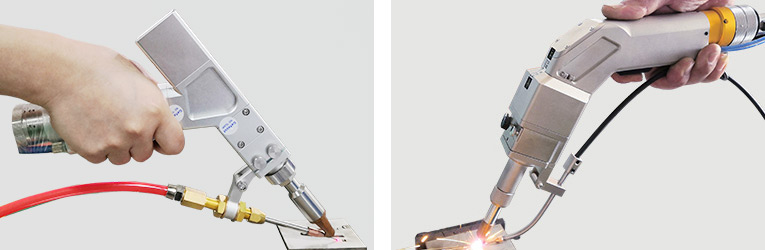

Flexible and convenient, arbitrary welding

Wobble Handheld laser welding head, light and flexible, can achieve any part

of the workpiece welding, lasting work is not easy to fatigue

|

|

Handheld automatic

wire laser welding der |

|

Handheld automatic

wire laser welding der |

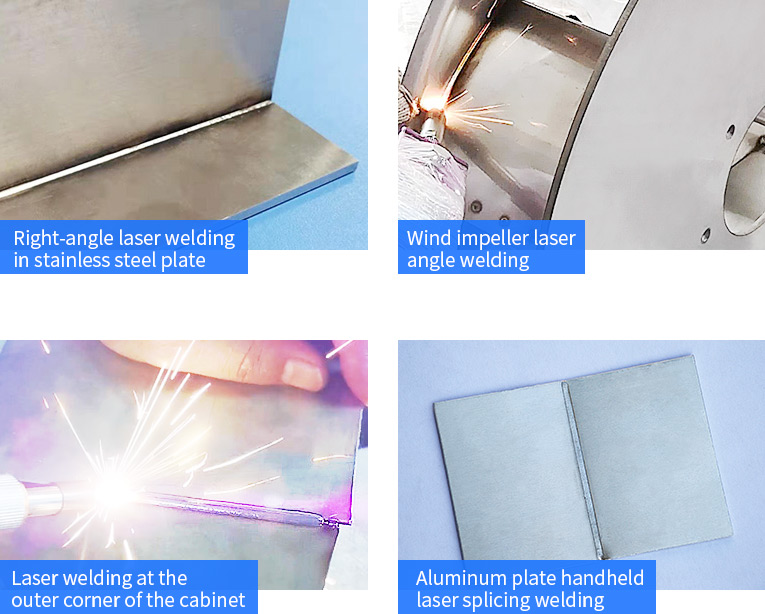

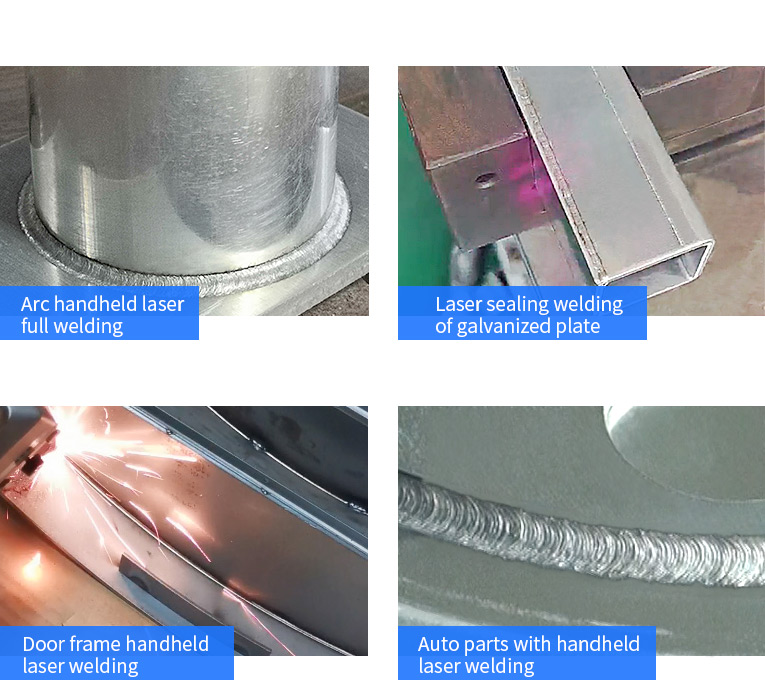

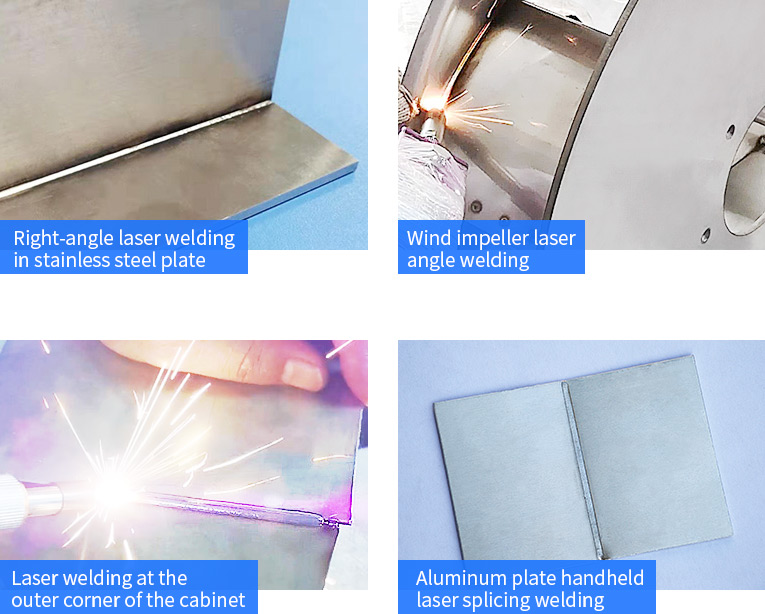

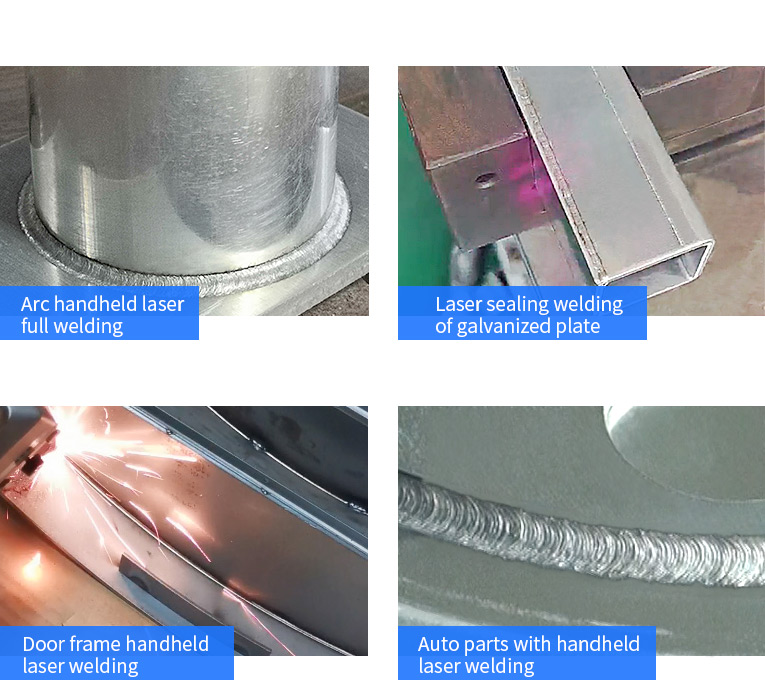

Fiber-optic laser welding machining samples

Applied range

Mainly for large workpiece, fixed positions such as inner right Angle, outer right Angle, plane weld welding, welding heat impact area is small, small deformation, and welding depth is large, welding firm. Is a more flexible welding process for long distance welding large workpieces.

Large and medium-sized sheet metal, cabinet, chassis, aluminum alloy door and window frame, stainless steel wash basin and other large workpieces of the inner and outer corner, the long distance spot welding, folding welding, full welding, sealing welding, etc.

Features of handheld fiber laser welding machine

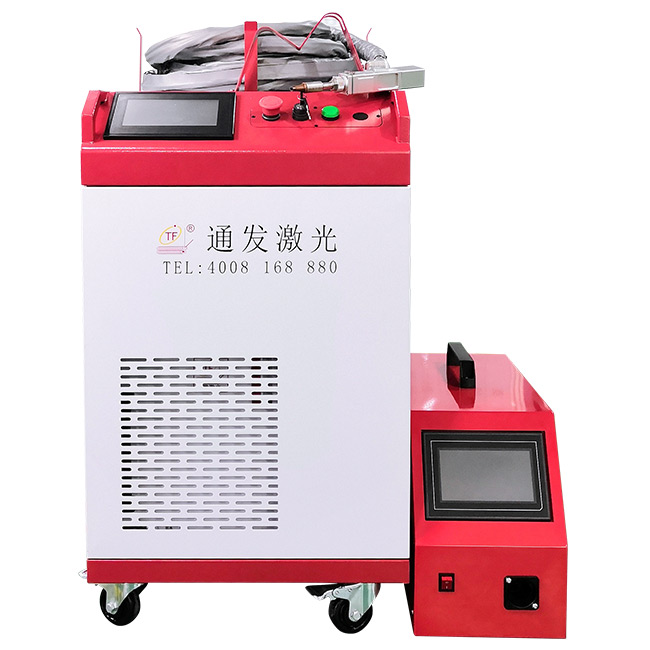

It covers a small area

Flexible and convenient integrated design, laser, water tank, control part combined together, covers a small area, low requirements for the site, equipped with mobile pulley, can adjust the station at any time according to the site requirements, convenient and flexible. Hand-held welding head, transmission optical fiber can choose 10 meters, break the limitations of the bench, can reach a wider welding range, suitable for a variety of complex welds, can be any part of the workpiece, Angle laser welding processing.

|

|

|

Good welding effect, firm weld joint

Continuous laser mode, smooth weld transition, no fish marks and firm weld; small welding heat influence area, small yellow and black area on both sides, and the overall deformation of workpiece is small; weld surface is high and small, without secondary grinding treatment to reduce labor and time cost.

|

|

|

Low use and maintenance costs

The optical conversion efficiency of continuous laser is more than 30%, 10 times that of solid YAG laser (3%), and the power stability is ± 0.5%; 3-5 times that of argon arc welding, saving at least 2 welders and 1 grinder a year. There is no optical lens in the resonator, the life of the pump source is more than 100,000 hours, and it is basically maintenance-free.

|

|

|

Product Parameter

|

Model |

TFL-1000FH |

TFL-1500FH |

TFL-2000FH |

TFL-3000FH |

|

Laser wave length |

1070-1080nm |

1070-1080nm |

1070-1080nm |

1070-1080nm |

|

Laser power |

1000W |

1500W |

2000W |

3000W |

|

Laser device output stability |

±0.3% |

±0.3% |

±0.3% |

±0.3% |

|

Fibre diameter |

100μm、20、50、100 |

100μm、20、50、100 |

100μm、20、50、100 |

100μm、20、50、100 |

|

Fiber length |

10 Meters |

10 Meters |

10 Meters |

10 Meters |

|

The spot can reach |

Φ0.2mm |

Φ0.2mm |

Φ0.2mm |

Φ0.2mm |

|

Pumping source |

Semiconductor |

Semiconductor |

Semiconductor |

Semiconductor |

|

Beam quality |

≤1.1 |

≤1.1 |

≤1.1 |

≤1.1 |

|

Aiming at positioning |

Red light + the inner and outer angles |

Red light + the inner and outer angles |

Red light + the inner and outer angles |

Red light + the inner and outer angles |

|

Power consumption of the host |

5KW |

6.75KW |

8.5KW |

11.5KW |

|

Electricity demand |

220V±5%/50Hz |

220V±5%/50Hz |

380V±5%/50Hz |

380V±5%/50Hz |

|

Cooling-down method |

Water-cold, deionized water |

Water-cold, deionized water |

Water-cold, deionized water |

Water-cold, deionized water |

|

Water cooling temperature |

27~33℃ |

27~33℃ |

27~33℃ |

27~33℃ |