Fiber laser welding machining sample pictures

Laser welding of battery bar sheet

|

Laser welding of battery bar sheet

|

Laser welding of battery bar sheet

|

Square battery bar sheet laser welding

|

performance characteristics

1.Welding head structure can be freely selected, fully meet the customer cost and site differences.

2.The equipment can be customized, separated and grafted, and can quickly connect with the customer production line.

3.Using the industrial control machine as the human-computer interaction, the operation is simple and reliable, easy to control.

4. Swing welding, through the angle deflection of the lens, can achieve multiple station welding.

5. Low equipment operation cost, less consumables, simple daily maintenance, and reduce the cost of line adjustment.

6. Compared with the inaccessible and inaccessible of traditional welding parts, non-contact long-distance welding can be implemented.

7. Wide range of applicable materials: stainless steel, carbon steel, galvanized, brass, aluminum alloy and other metals.

Applied range

Scope of use: metal copper, iron, aluminum, stainless steel and other large specifications of long products multi-angle processing.

Equipment advantage

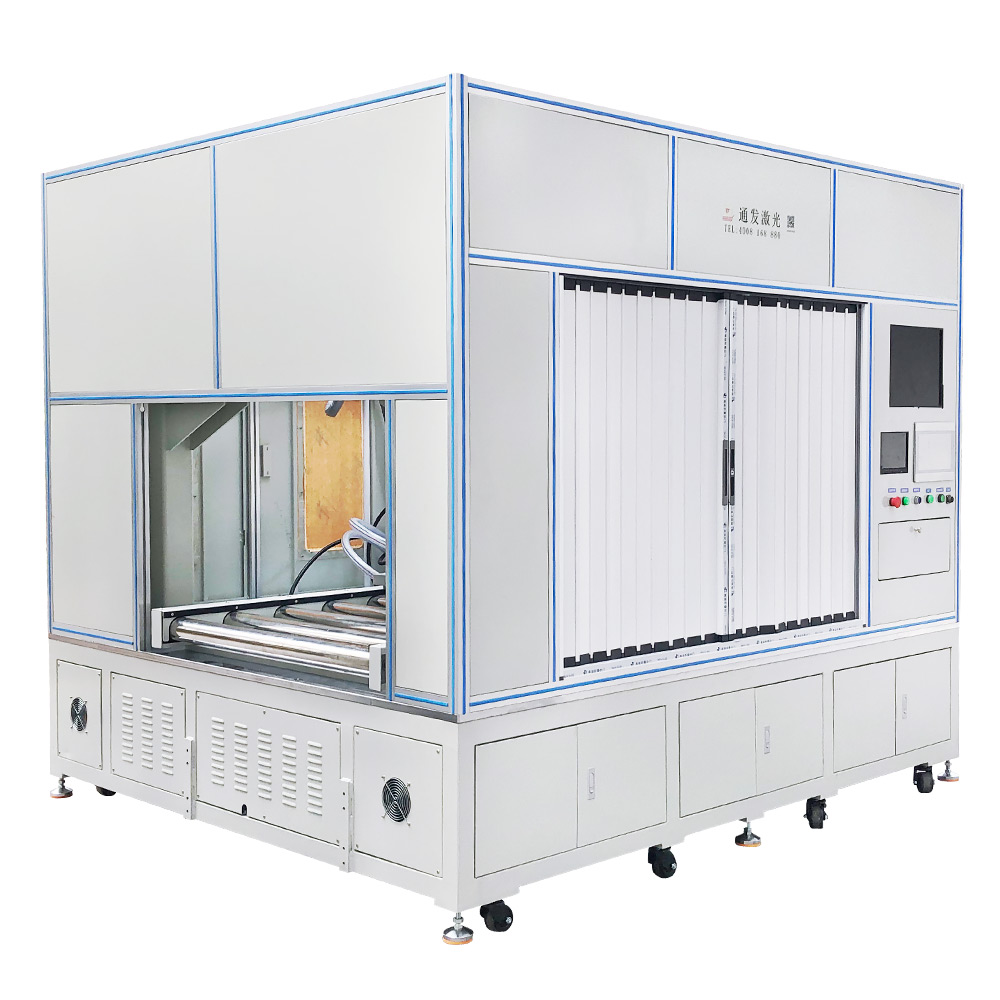

Fully enclosed automatic production line equipment, external safety grating, automatic delivery tray.

Flexible: drum type, double speed chain mechanism, suitable for a variety of specifications of battery welding cleaning.

High precision: each process adopts precision machining and assembly, and the process deformation is strictly controlled.

Weld characteristics: standby to ensure that the gas box weld is full, good sealing, melting depth is not less than the thickness of the thin wall side, welding stability, etc.

Equipment system: dual vision system (improve efficiency), height measurement system, conveying drum mechanism, welding control system.

Processing head: vibration mirror welding head, suitable for circular straight arc track cleaning and welding.

Standard workbench

|

Laser welding machine six-axis manipulator

The manipulator in laser welding has been fully utilized, especially the automobile assembly line welding, the use of manipulator can achieve unmanned workshop production, efficiency is greatly improved. This manipulator is 5 axis control, machining radius is optional, can achieve the laser welding of large products.

|

|

Laser welding machine horizontal workbench

Horizontal workbench, using the four-axis linkage control mode, can weld and process special-shaped products, Z-axis can be customized according to the different needs of customer products, the installation position can be increased, can also customize the customer needs to travel.

|

|

Laser welding machine automatic bench

The workbench can be linked with four axes to realize the spot welding of the curved surface.

|

Professional laser welding PC motion control system

1. Use the mature solution of industrial motion control to integrate the laser welding machine and motion control into the PC operation interface of the machine.

2. Powerful PC control, easy to program, debug and maintain. Can complete automatic or semi-automatic spot welding, butt welding, stack welding, sealing welding, for the complex plane straight line, arc and any track of welding.

3. The software adopts IDE integrated working environment, and the main interface integrates graphic editing, operation monitoring, acquisition and programming, and motion control. The layout is simple and professional, which can effectively improve work efficiency.

4. Real-time control, without other PC operating system plug-in.

5. High performance motion control can be carried out on the 4 axes to realize the programming of welding trajectory in space.

6. Provide multi-language display (simplified Chinese, English, etc.), and support international applications.

Open laser PC motion control card

|

Operating interface of welding software of common hair laser welding machine

|

Operating interface of welding software of common hair laser welding machine

|

Operating interface of welding software of common hair laser welding machine

|

Product Parameter

|

Laser model |

TFL-6000F-KC |

|

Laser wave length |

1070-1080nm |

|

Laser power |

6000W |

|

Laser device output stability |

±1.5% |

|

Laser weight |

70kg |

|

Fibre diameter |

75 μ m fiber core 3mm / mrad |

|

Fiber length |

20 Meters |

|

The spot can reach |

Φ0.2mm |

|

Pumping source |

Semiconductor |

|

Beam quality |

≤3.0 |

|

Aiming at positioning |

Red light + CCD camera surveillance system |

|

Laser host power consumption |

≤18KW |

|

Electricity demand |

380v±5%/50Hz |

|

Cooling-down method |

Water-cold, deionized water |

|

Water cooling temperature |

23 ℃ |

More non-standard laser welding schemes can be customized on demand

Laser welding machine for auto parts Lighting accessories, laser welding machine

Automobile press, laser welding machine Automobile press, laser welding machine

Laser welding machine for auto parts Aluminum-frame laser welding machine